A purchase order is a legal contract between the buyer and seller. It’s a financial agreement between each party. It’s also known as a PO within the inner circles of people that deal with fashion production documents on a small business or a larger enterprise. A purchase order is probably one of the most important documents within the industry, which include tech packs and BOM just to name a couple

How Do Purchase Orders Work in the Fashion Industry?

We will outline the purchase order process and its protective nature. Next, we will examine how to track the purchase order.

The PO Creation

The lead buyer is responsible for creating the purchase order. They will liaise with the financial department to ensure accuracy. Multiple individuals will review the purchase order to prevent any mistakes.

The Buyer then Sends a PO for Seller Approval

The buyer collects all necessary information and creates the PO to send to the supplier for approval. Vendors should be informed when document approval is needed to avoid shipping delays. Approvals are timestamped to ensure agreement between parties.

The Seller Checks The PO Information

The manufacturer reviews the purchase order for accuracy and capacity. They also check their supply chain and negotiate their own price, raising purchase orders with suppliers.

The fashion apparel industry involves multiple companies, so a standard purchase order is necessary to prevent confusion.

The Purchase Order Approval

The purchase order is a contract between the parties, with three parts: Offer, Acceptance, and Consideration. Once the seller approves the order, the supplier fulfills the order.

The factory manufactures the goods and generates a purchase invoice similar to the PO. Payment terms vary based on the relationship between the brand and manufacturer, with a 50-50 payment process being widely used.

The PI may need updating due to overproduction for quality control purposes. POs typically allow for a 5% under or over without penalty.

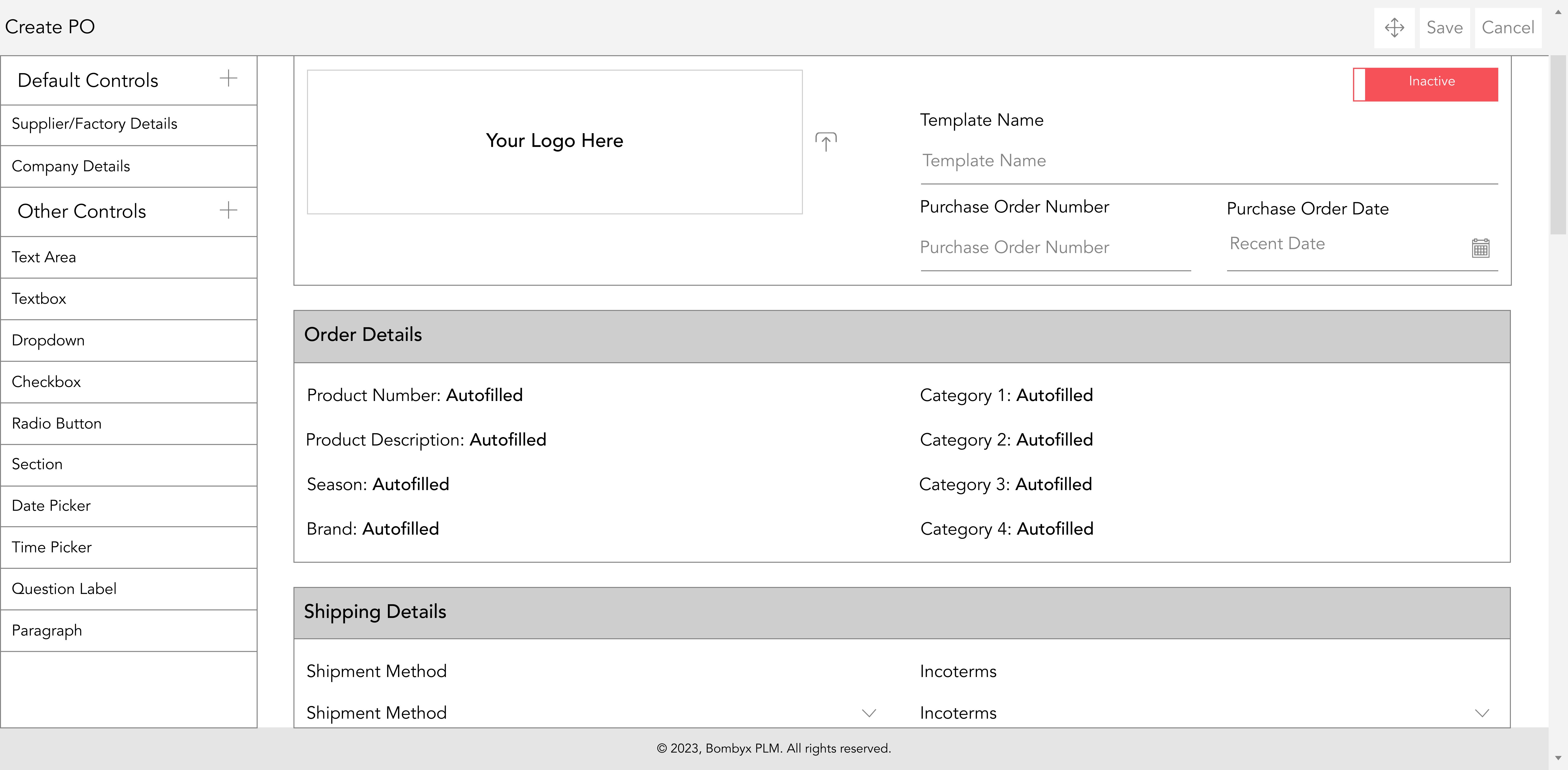

So What Makes a Purchase Order Template?

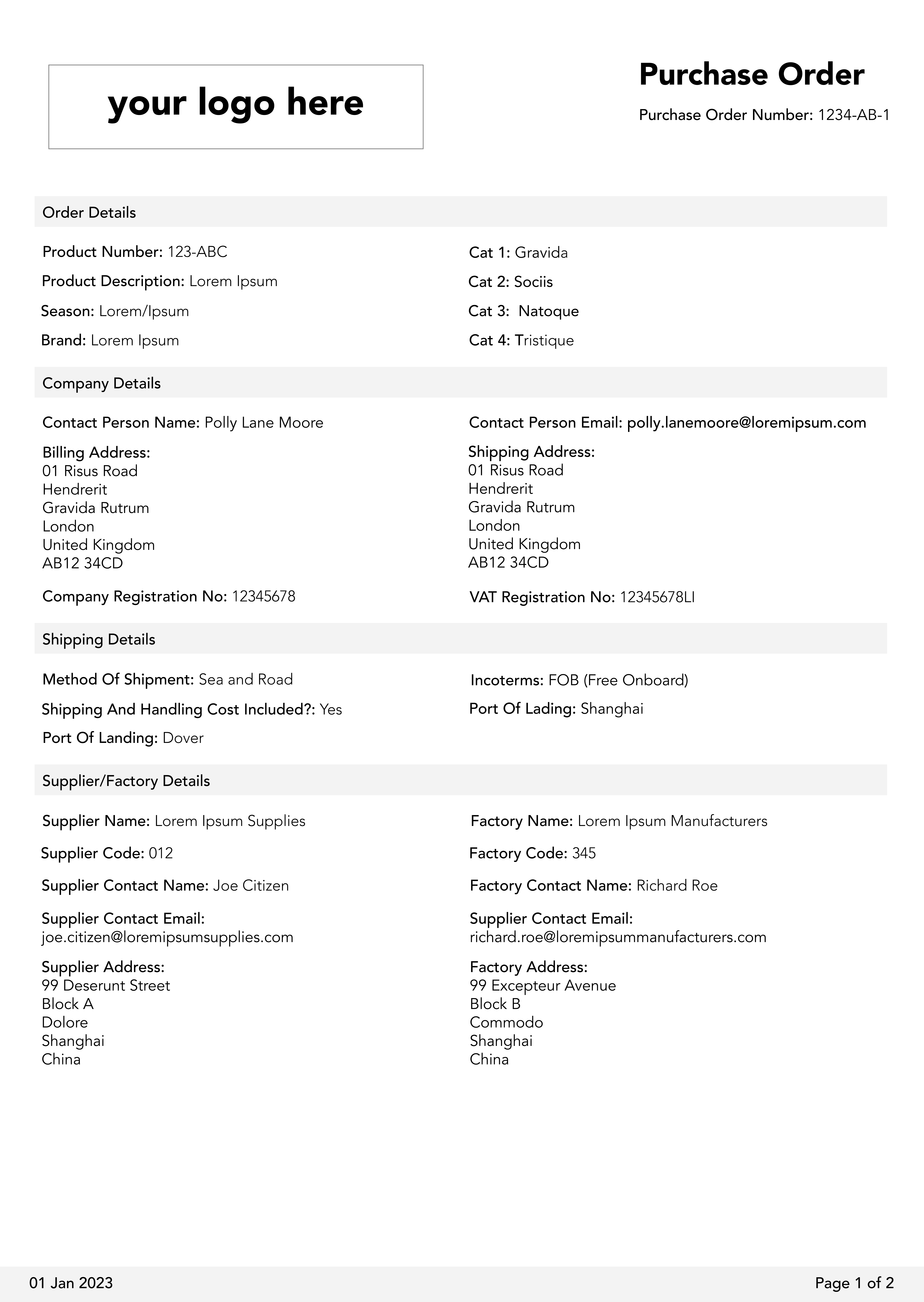

Purchaser Information:

This normally includes the following of the brand’s information, such as the Name of the fashion Business, Company Logo, business address, contact details, and purchase order number and date.

Supplier Information:

You need to showcase the specific receiver of the PO. This is where you will list all supplier’s companies and their business addresses. If they have a company number, you can add this as well. Providing as much information about the companies helps.

If you are working with a UK company, you can check the company on Companies House to find out any information about the business.

Shipping Information:

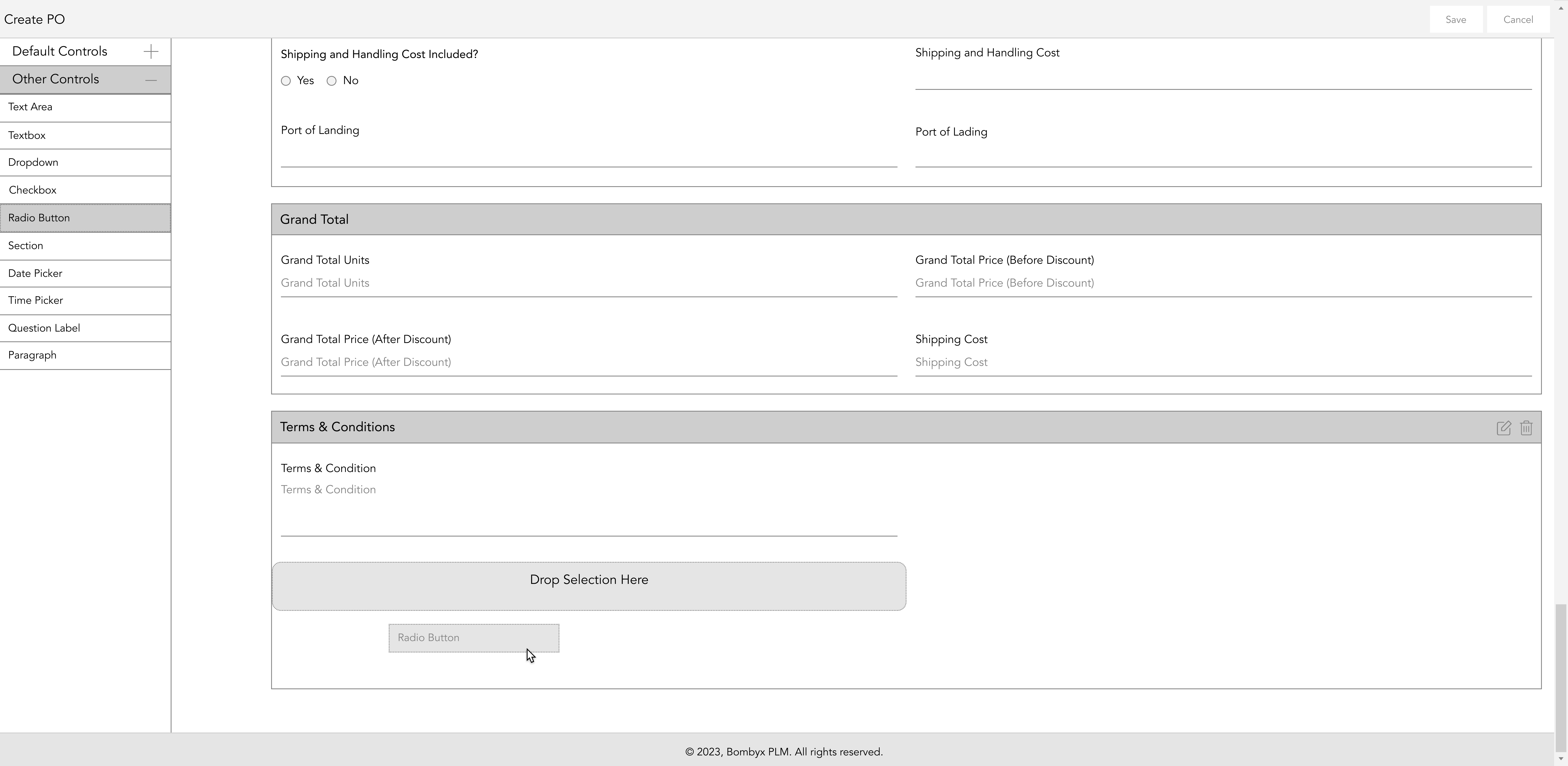

This should include the following, so mistakes happen as it can turn out to be very expensive if the information is wrong. It should clearly state where the products are getting shipped to, the shipping method and terms, and when the products should be delivered by.

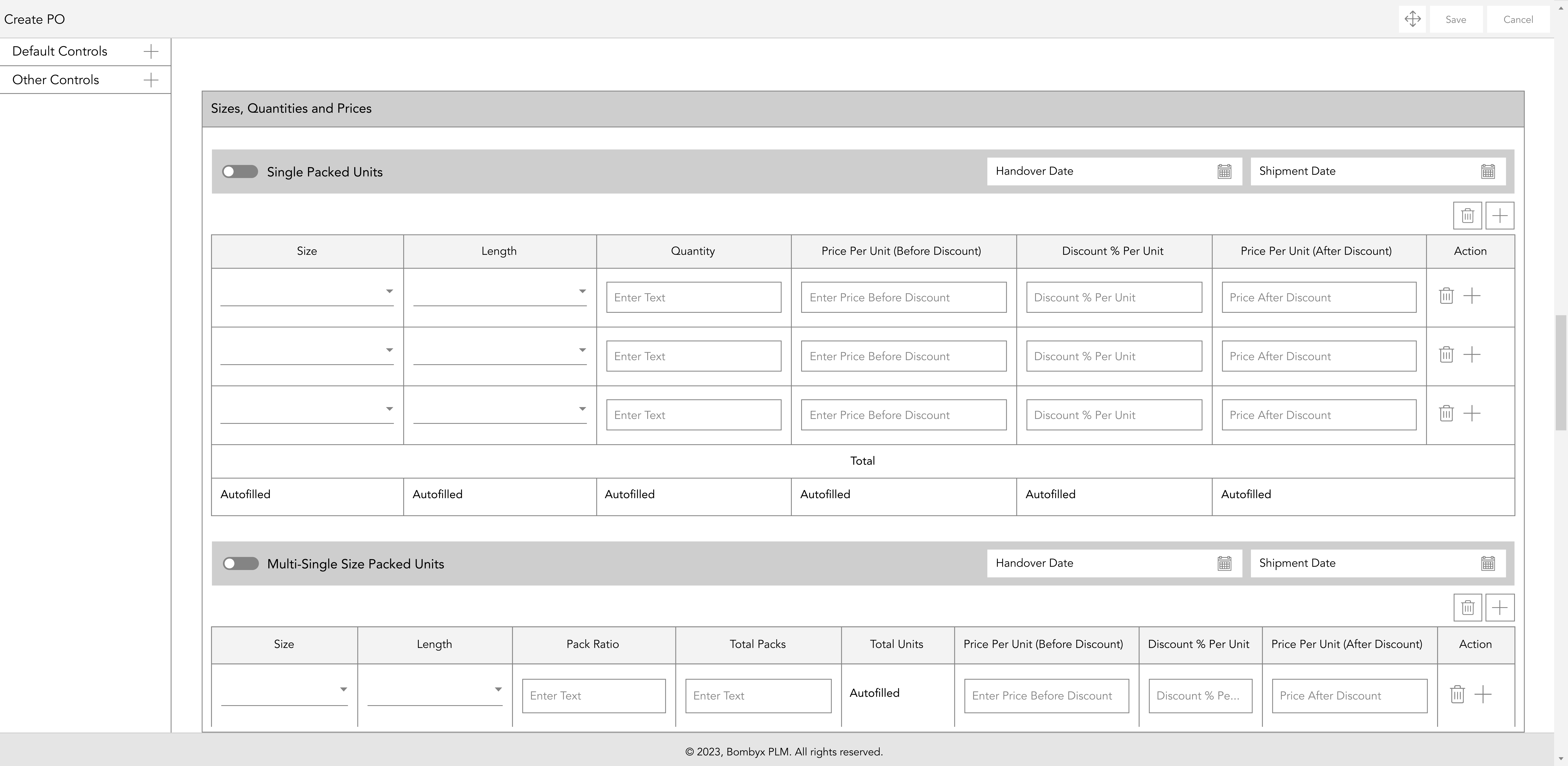

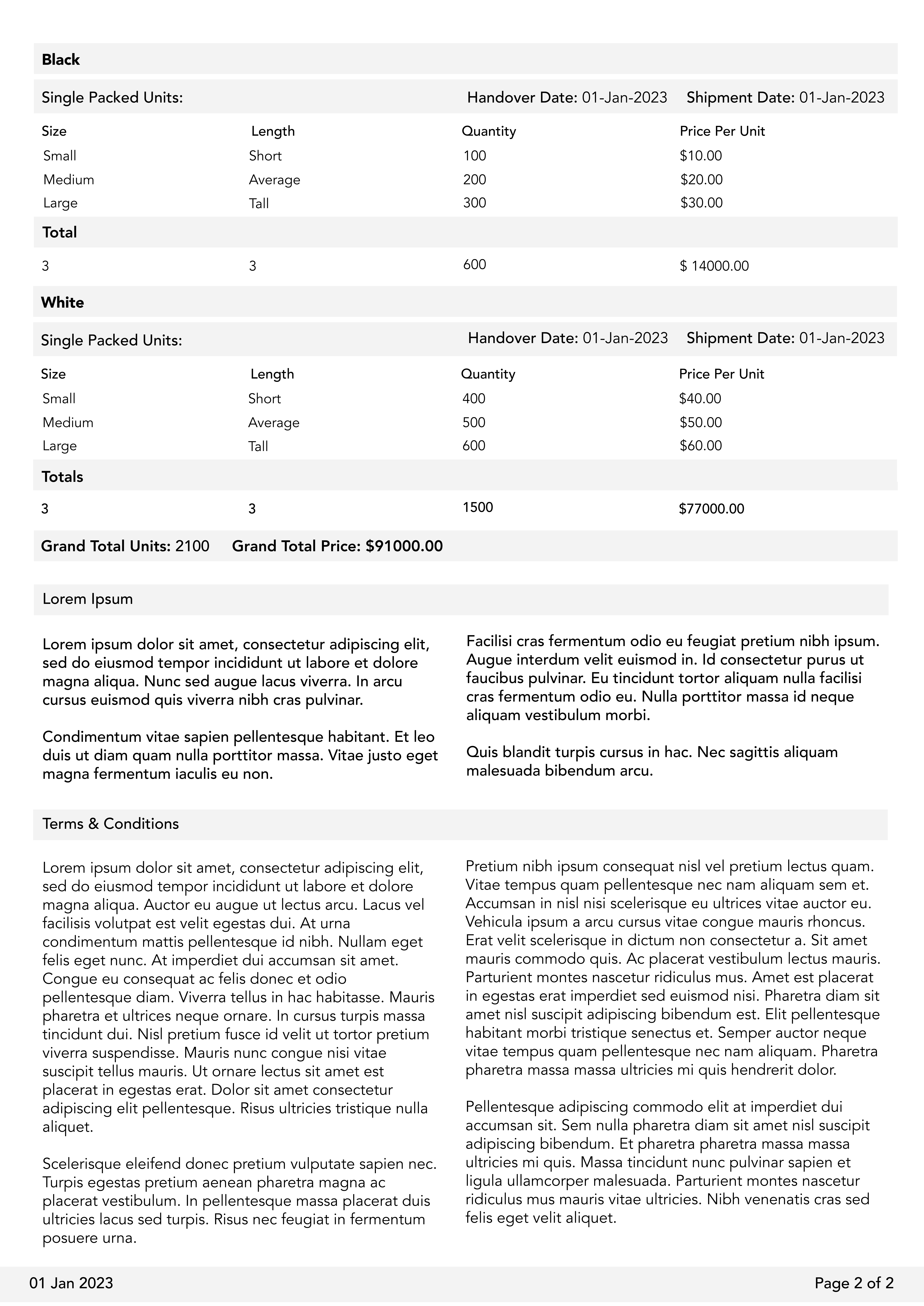

Order Information:

Every fashion brand should try to include as much information as possible with everything clearly listed in the purchase order. For every item, it should include the product code or SKU number, quantity, price per unit, and item description, along with the expected delivery date. You may find that factories split orders depending on their own production timelines within the factory. Some fashion brand owners may also include labeling and packing information.

To Summarise

The purchase order needs to be completed by providing the vendor with a subtotal, shipping costs, Vat (or other taxes), discount, and, of course, any contingency or caveat. A great example of a caveat would be “The payment and order are subject once approval has been met with the fabric quality and texture.