system masters

your system, your way.

Bombyx lets businesses customise the system to use their own language, which eliminates confusion from industry-specific terminology. The customised system includes product categories, units of measure, and sample terminology.

Users can rename system modules to create a “white-labeled” system tailored to their needs. This means businesses no longer have to re-educate their teams to a new language, making the transition to a new system seamless.

functions

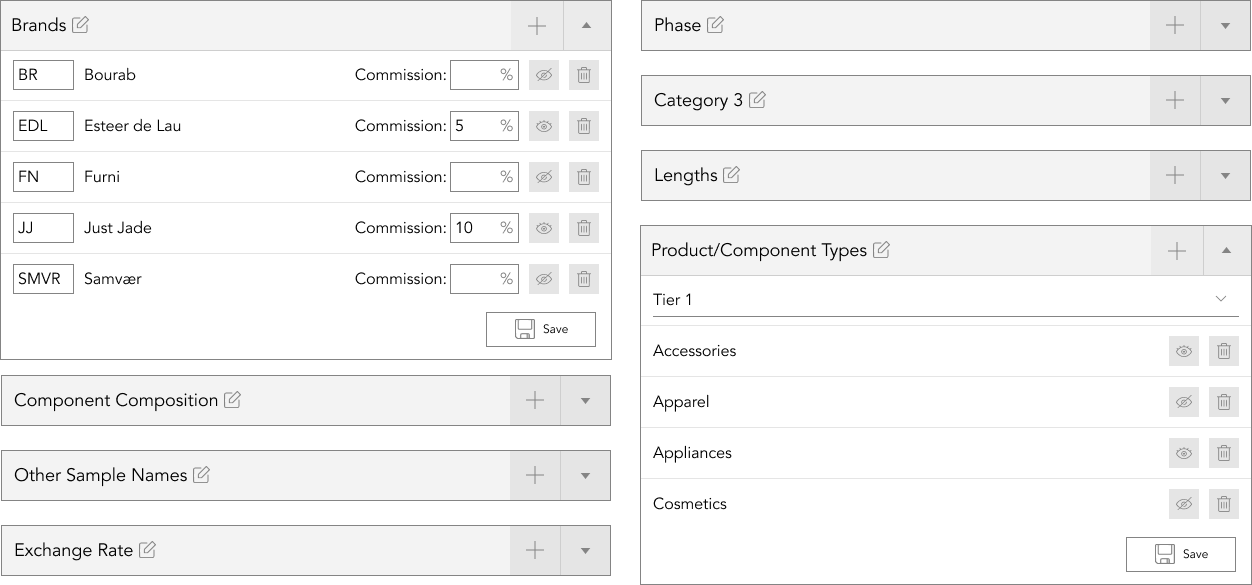

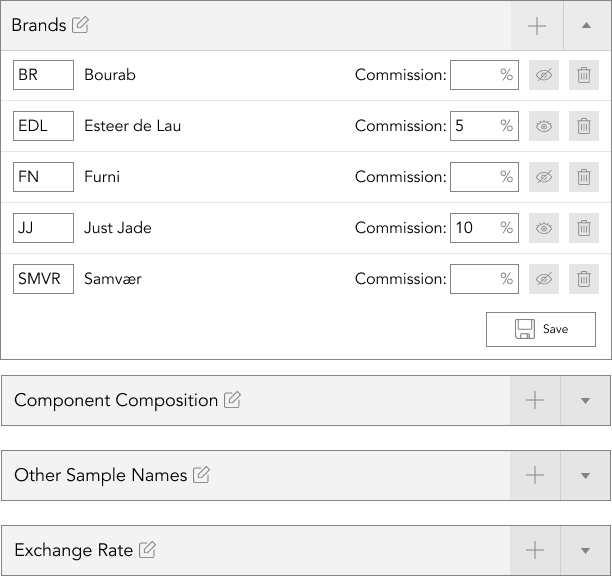

brands

Users can assign brands to products and filter or assign user rights to individual brands. If in partnership with the listed brand, users can apply the commission they’ll earn off the back of the product, with the amount being automated in the landing information of a product costing section.

phases

Phases (or seasons, depending on product/industry) aid users in referencing a product across multiple seasons with varying differences. Users can specify a product release name, assign a month and year along with the phase name.

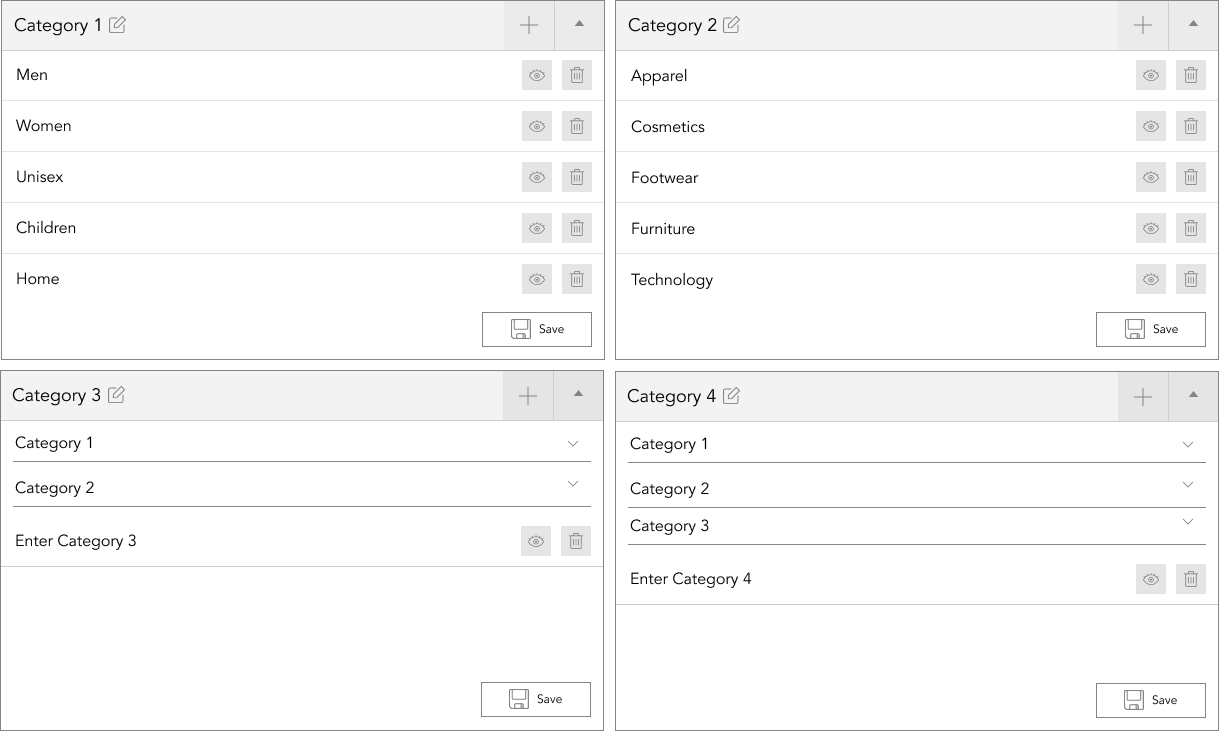

categories

Bombyx offers a structure consisting of up to four categories, but it’s not mandatory to use all four if they don’t align with your business’s structure. In fact, we are quite flexible, allowing you to create as few as two categories if that is all your business requires.

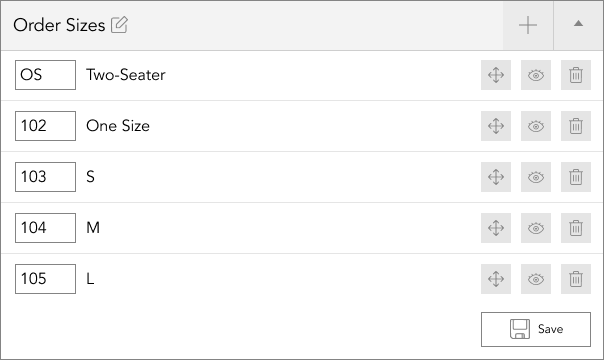

order sizes

Here, in order sizes you’re able to list every size you’re likely to produce products in which can be used in creating your purchase orders that are sent to your supply chain in order to develop and product your product ranges.

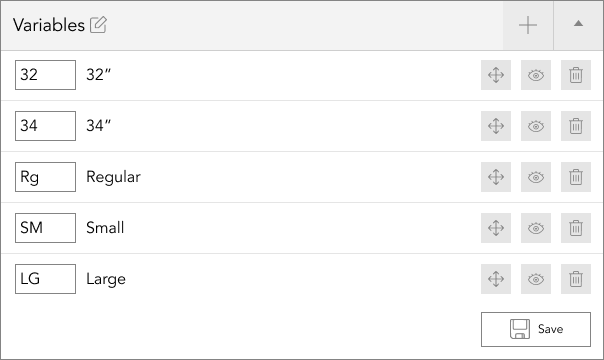

variables

By using variables, businesses can keep one source tech/data pack for products that have varying factors, such as multiple lengths for the same product. This allows them to display the varying options while keeping everything together in a single source of truth.

units of measure

By creating a system master, you can list all the unit of measure options necessary for accurate product measurement and recording in Bombyx. This compiled master can then be used to retrieve size or weight data for any field requiring a unit of measure.

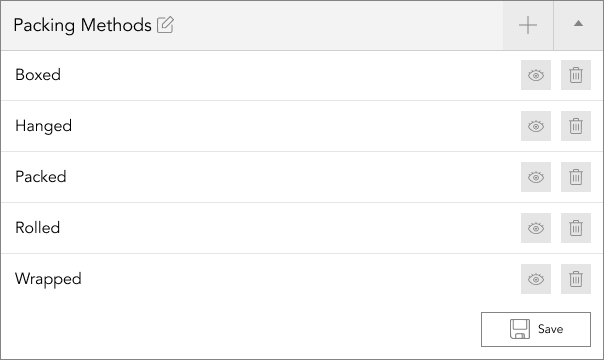

packing methods

To ensure that your supply chain knows how to pack your products, packing methods are displayed in two places. They are shown on the top-sheets of documentation, as well as on the product display card. This information will help ensure that your products are packed correctly in their cartons before they are dispatched to businesses or consumers.

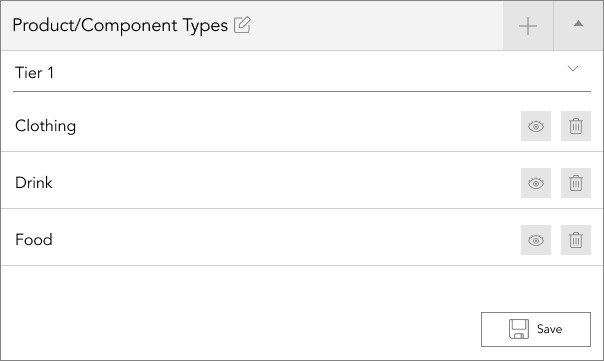

product/component types

You can display product and component type data up to four tiers in Bombyx, including raw material extraction, processing, materials production, and finished product types, depending on the area you’re using. This allows for the creation of consistent product or material data throughout the system.

product statuses

With every business being unique and having its own set of values that define their stage and status, Product Statuses enables businesses to define at what point the product is in its lifecycle of development. Whether it’s in development, active, an order, cancelled or something else, you’re able to define it in your business’ own way.

bom sub-types

Further define your Bill of Materials through listing the sub-type of your components material to help your suppliers understand the data their sent more precisely. With BOM sub-types, users are able to provide accurate Bill of Materials for ever party to remain on the same page.

component placement

Keeping a master of your component placements not only lets partners know where that material will be used, but also enables further range plan analysis to identify fabric minimums that need to be met by fabric mills. It also helps to keep order and consistency when it comes to business termonology.

component finish

Listing variable finishes is crucial when dealing with components that have multiple variables such as gloss, matte, and others. It prevents confusion and misunderstandings when working with supply chains and building up bills of materials. Additionally, it ensures that everyone involved has the necessary information to accurately cost the product.

component composition

Centralize your material compositions for easy reuse in Bombyx. Avoid errors caused by varying names or spellings and streamline your bill of materials, costings, and purchase orders

e-comm specs

E-comm specs are ideal for PIM. They enable users to choose specific dimensions from detailed specification charts to use in e-commerce or other marketplaces. Just specify height/length, width, depth, etc, and the system feeds the data to your range plan, PIM, and beyond.

sample names

Customize sample names to fit your business needs in Bombyx. Whether you refer to your first sample as an ‘Initial Sample’ or a ‘Prototype’, it’s fully customizable. Simply enter your preferred terminology for sample sets and use it going forward.

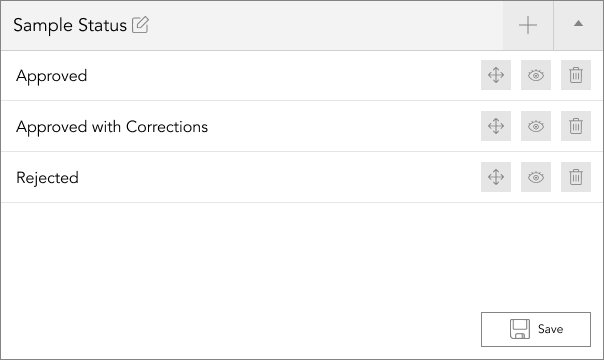

sample statues

Customize product development instructions to your business needs in Bombyx. Status updates such as ‘Approved’, ‘Approved with Corrections’, or ‘Rejected’ can be tailored to communicate the next steps to your supply chain.

sample tracking

Track product development samples through Bombyx from request to sign-off, including receipt and forwarding within the business. Suppliers can also provide tracking numbers/URLs and receive comments through the system upon sample arrival.

exchange rate

Apply exchange rates to landed cost calculations with Bombyx’s system master for automatic record production. Manually add exchange rates or use the system for hedging/pre-booking currency, and calculate profit margin % and markup with ease.

custom attributes

Create custom attributes with text fields or dropdown menus for critical attribute communication in Bombyx. These attributes are visible on product cards, document top sheets, and the range plan, and can be applied to products for better business and supplier communication.

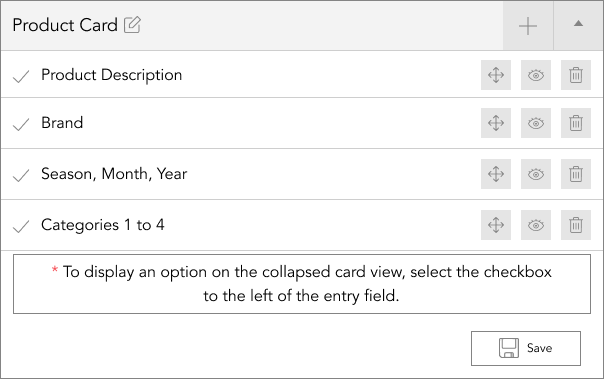

product card

Arrange your product card information in a specific order with Bombyx’s collapsed and expanded views. Keep key data visible always, and access additional data at the touch of a button.

product modules

Turn off modules not required for a specific product type to streamline the system and eliminate unnecessary buttons. This boosts efficiency by providing users with only the required modules for productive work.

libraries, groups, and templates

Similar to the product modules, if for whatever reason your business doesn’t require a specific library, group, or template module, simply switch it off and hide it from sight of your company’s users, keeping them in complete focus.

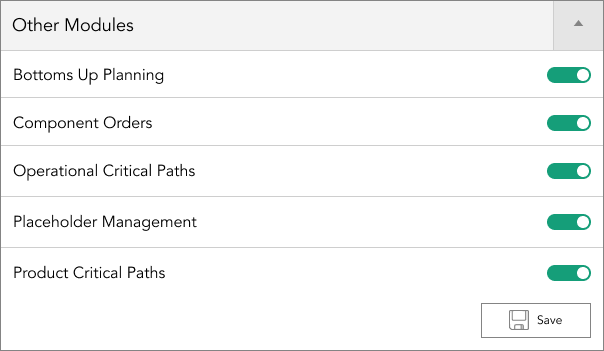

other modules

Additionally to the product modules and libraries, groups, and templates modules, if any of the other modules aren’t needed, like the other two, hide the access of these modules from users. A tidy system is a tidy mind!

renaming modules

Different businesses may use different names for the same process or practice. Bombyx offers a renaming module, allowing users to easily identify modules by renaming them to their preferred terms. With Bombyx, the system works for you.

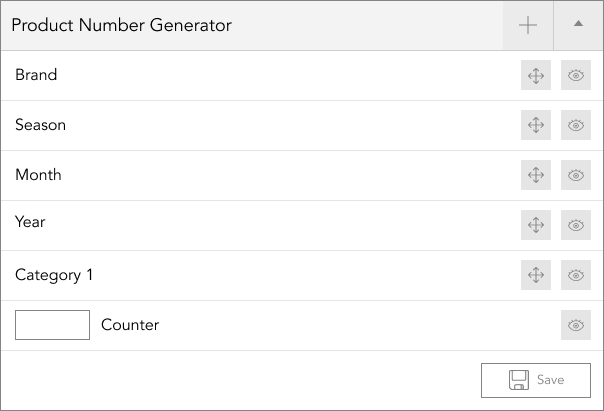

product number generator

Simplify product numbering with automatic numbers based on attributes like brand, season, and fabric, eliminating repeat numbers caused by counting errors between colleagues as your product range expands.

sku generator

Bombyx generates SKU numbers for products using identification attributes, providing a consistent and accurate approach. Brands can choose which attributes to use, allowing for unique SKU numbers tailored to their system.