In fashion manufacturing, discussing the critical path takes up a significant amount of time. To ensure production runs on time, it’s essential to receive the critical path in advance.

If you’re unfamiliar with this concept, this post will explain why it’s crucial. Your business will benefit in the long term from understanding the importance of the fashion-critical path. So, let’s examine what it is and why it matters to your business.

What is the Critical Path?

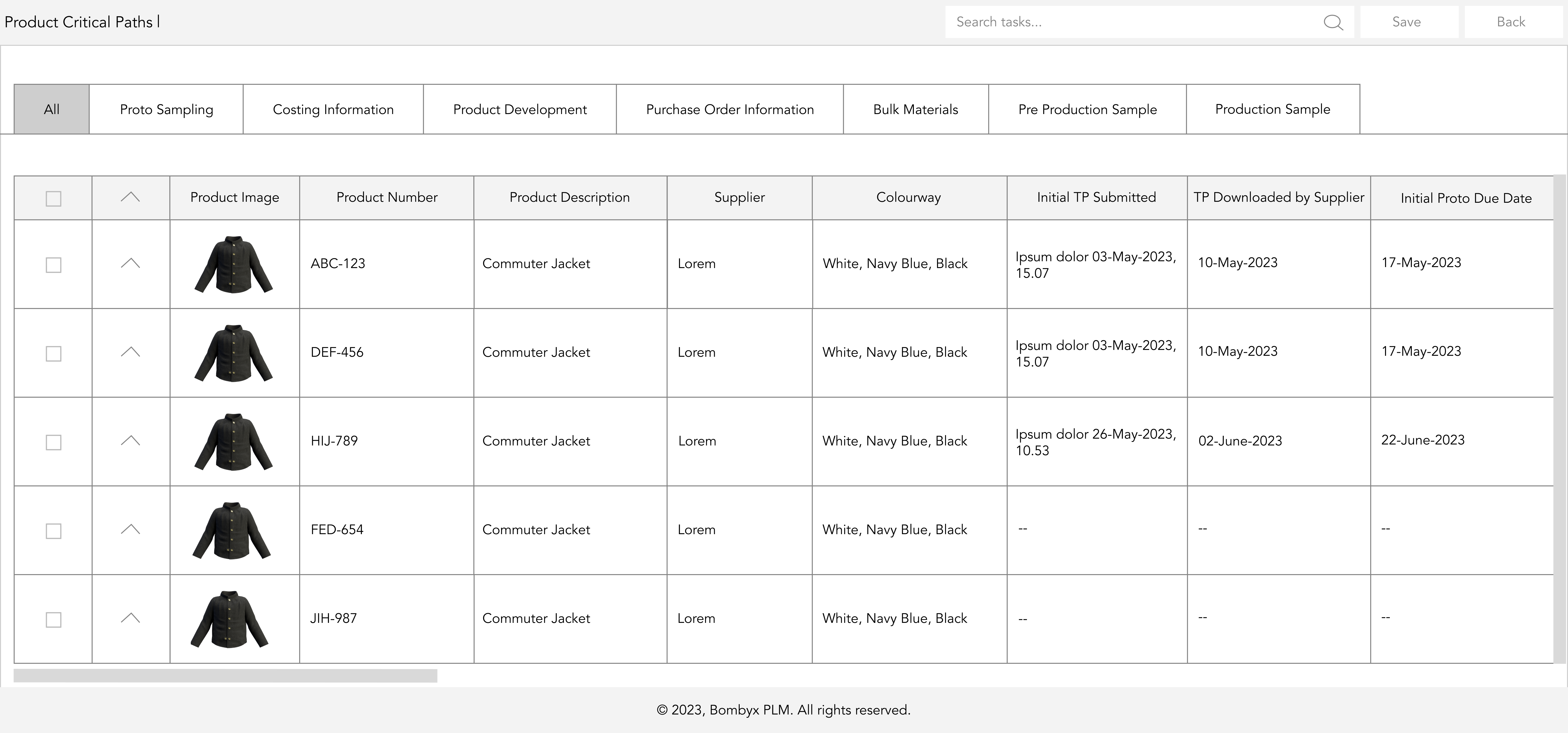

The fashion industry’s production plan includes all activities completed within certain time frames for on-time shipping and determining the estimated time of delivery (ETD).

A well-organized critical path is crucial to identify any crucial tasks, prevent delays, and ensuring all parties involved meet deadlines.

Originally adopted by DuPont in the 1950s, this method has since been applied to other fields, such as hardware, software development, and research products.

It expedites the product’s journey to market by allowing for the handling of workflow and efficient role assignment.

Why is the Critical Path Important?

The critical path is vital to mitigating issues when suppliers handle multiple product designs, development, material sourcing, and testing in fast-paced fashion production, which can take as little as 40 days.

Creating a critical path for product development is crucial, even if sourcing raw materials from one location.

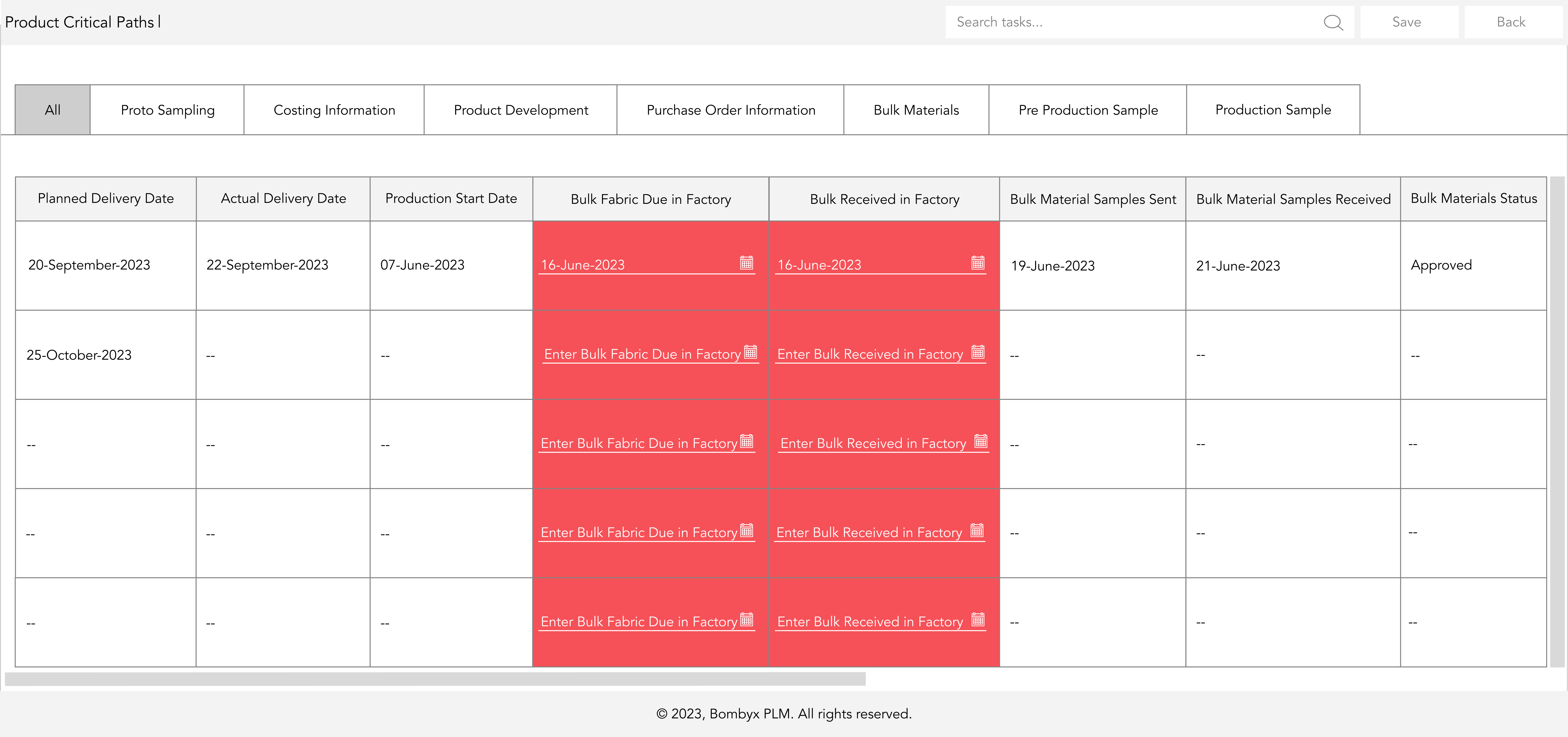

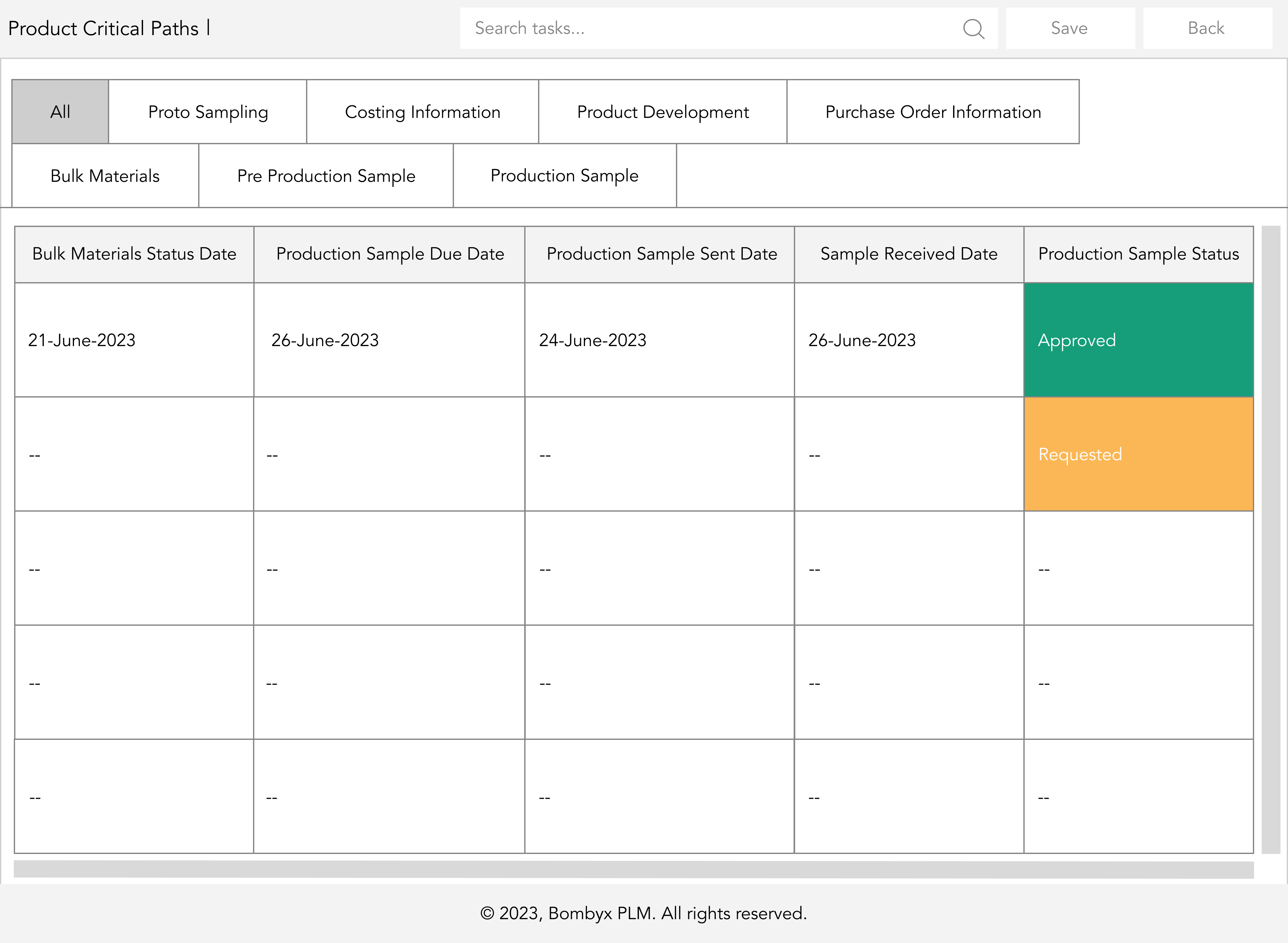

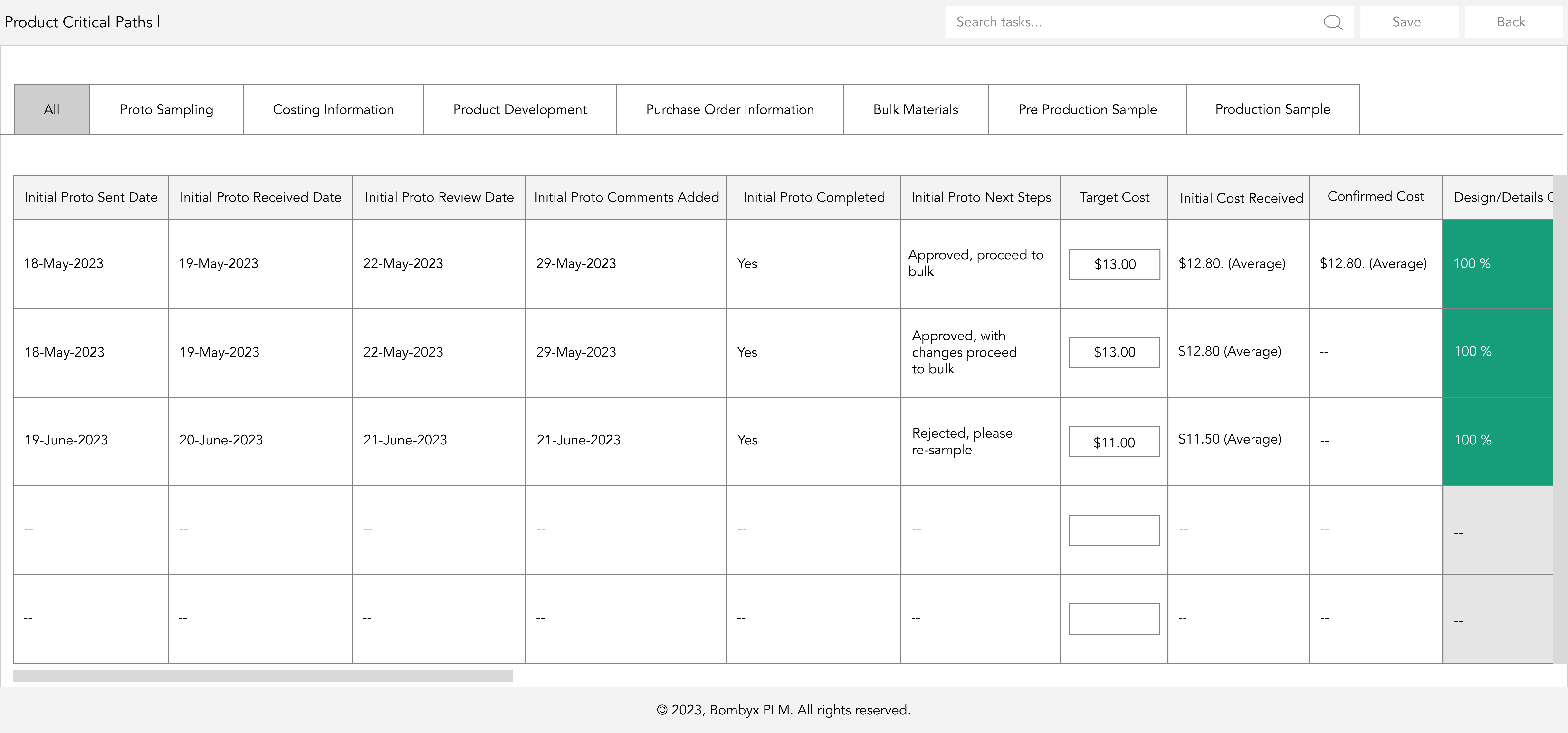

Managed multiple factories, including deadlines for first and second sample approval, sealed sample production, production placement, order completion, and delivery to the warehouse in the tech pack design process.

Learn how to Set-up a Critical Path for your production

To set up a critical path, take several steps. Know the origin of all materials required, and determine the time needed to receive supplies once the order has been placed.

Before showing the range to prospective buyers, have in-depth knowledge of lead times for fabric and trims to avoid committing to items with long production times and high minimum order restrictions, which can cause delays.

Ensure necessary items are readily available to prevent future issues. Remember that overseas manufacturers may have different holidays than your location, so plan accordingly in the critical path.

Plan for delivery success

To ensure the smooth execution of dockets, communication with the factory is crucial.

Factories have a queuing process, so missing materials delays product delivery and cause lost orders. A tech pack with all details and finishes helps, but factory performance can still be challenging.

Picking the right visit time is important, as busy periods like spring and summer can cause bottlenecks and longer delivery times, especially for Christmas production.