Massive effects exist in supply chain management. Pre-pandemic, supply chain managers’ roles were less understood, but now their impact on daily life, enabling access to essential products like food and cars, is widely recognized. The pandemic disrupted everything, reshaping consumer perceptions of supply chains.

In the current fashion and consumer goods market, companies face the harsh reality of optimizing supply chains. Challenges include factory lockdowns, rising inflation, labor costs, and material shortages. With consumer demand for sustainability, the industry must prioritize improvements.

The pandemic was a shock, separating adept supply chain managers from those who struggled and left the industry. This emphasizes the need for robust software management systems.

What are the changes within supply chains?

Back in August 2022, a survey was conducted by Gartner, and by looking at the results, we can see what changes they made. So 74% have made changes to their business by increasing the number and sizes and locations within their supply chain within the last 2 years. Then 51% out of the 400 companies responded by saying they increased the number of locations.

Reducing the supply chain risk

Regardless of which of the supply chain management model, companies have adapted to. You can safely say that they all needed to improve the methods that they previously used to improve the risk management aspect of the business.

Before the pandemic, it was hard for businesses to justify any investment into improving technology. But, as supply chain risk management has had to adapt, so has the technology associated with it. Like in other businesses, the system has to get tested to breaking point, so you know what has to be done to improve it.

This is why most systems never really get updated until after it’s been stress tested by a disaster.

The harsh reality over the last few years and the impact it’s had, more companies have now opened up to investing in better solutions. Some of these systems have advanced algorithms in place that can identify risks in real-time, sadly this is only limited to one tier up within the supply chain.

This is progress and things can only get better with machine learning of data as the software progresses. The “N tier problem” is more of a challenge in locations such as in Asia and other complex supply chains with materials arriving from all over.

Taking a deeper look into Your Supply Chain

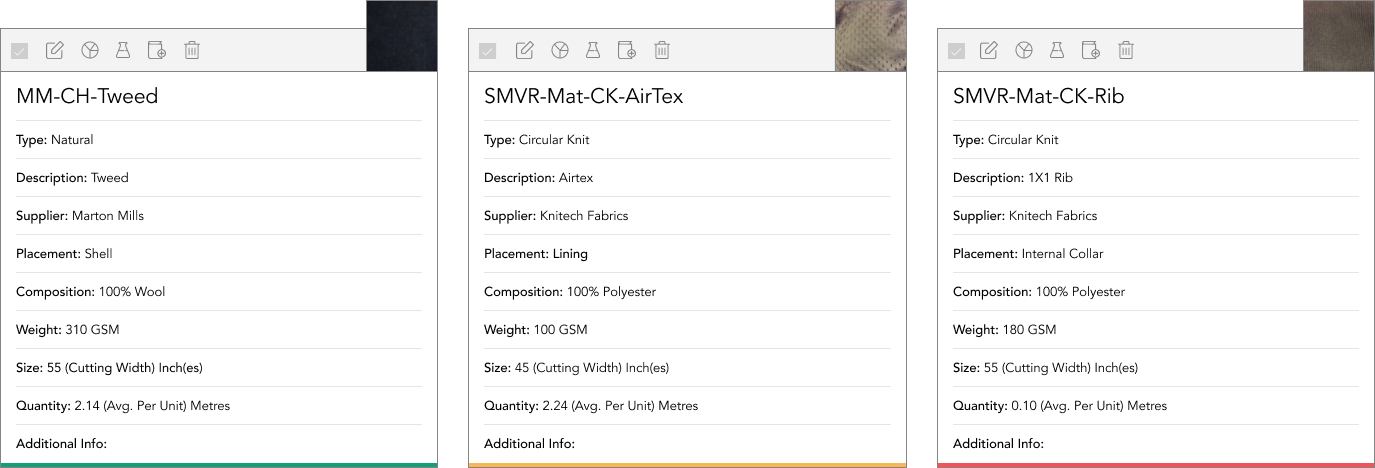

Using product lifecycle management software like Bombyx PLM can help your business manage its supply chain even better. If you are using tech packs, this can help you manage the material supply chain by having the correct bill of materials filled in correctly.

This is the type of data that can make the product to market move a lot faster and without mistakes or errors. Having software will built-in features that enable you to work smarter and faster will cut down the supply chain delivery time down.

As technology moves forward so fast, it’s important that supply chains keep up with the changes. As the data shows above, most are making change one way or another to be able to keep to the tight deadlines.