There’s a business case for sustainability. Consumers are more discerning and interested in brands that prioritize the environment, and are transparent about their operations and green initiatives.

Sustainability must be applied to the entire supply chain, from design and production to product use and disposal.

So Where do you Begin With it all?

“Knowledge is power,” they say, so gaining a deeper understanding of your goods and services’ environmental impact is a good first step. Then, you can make improvements as required. A lifecycle sustainability assessment can help determine your supply chain’s carbon footprint by identifying resource consumption, energy use, and waste emissions.

The design stage, responsible for 80% of a product’s environmental impact, should be a priority. Eco-design benefits include cost savings, increased customer satisfaction, and regulatory compliance.

What Tools and Techniques are Available?

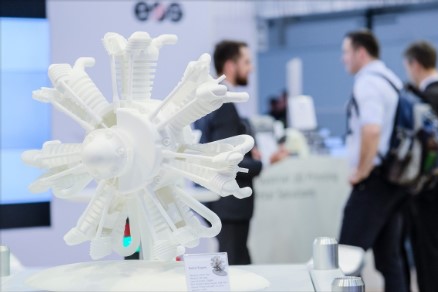

There are various technologies that can help you achieve your sustainable lifecycle goals. The technology you choose depends on your overall goals. Additive manufacturing is a strategy that can help to simplify and refine the manufacturing process. With additive manufacturing.

You can create intricate designs and parts quickly, saving time and energy. It generates less waste and provides more potential for eco-friendly design than subtractive manufacturing.

PLM is another tool that can give your business a serious boost. It can simplify the measurement and analysis of a product’s impact, making the supply chain more transparent, and improving transparency for consumers and stakeholders.

To learn more about how PLM can help you become more sustainable, contact the Bombyx team today!