What is a PLM System

PLM stands for product lifecycle management In order for us to effectively grasp the understanding of PLM’s existence and its increasing necessity; we must dig a little deeper into the origin by first understanding the product lifecycle.

The Phrase ‘Product Lifecycle’

A product lifecycle represents a series of changes in the lifetime of a product. Regardless of product differentiation, they all share the same stages throughout their lifecycle. Now if anyone wants to know the stages, today’s modern technology has made it very easy to search for answers.

Plus, searching on the internet for ‘product lifecycle stages’ will only take a few seconds. However, finding the correct answers, can be time-consuming and not to mention frustrating. Therefore, we have taken the liberty to do the research for you. Moreover, explaining in a simple way to easily understand and most of all remember.

The Product Lifecycle Theory

Primarily, the theory we vastly know and follow today was invented by an economist named Raymond Vernon in 1966. On many occasions, Vernon referred to it as the ‘International Product Life Cycle’. However, if we search further. We will find the concept of Product Lifecycle is dated back to 1931. Referencing Otto Kleppner. who first pondered over a theory, stating that a product goes through 3 stages:

- Pioneering

- Competitive

- Retentive

Two decades later, a man named Jones in 1957 working at that time for Booz Allen Hamilton looked into the theory and restructured it into 5 stages. He believed that not only should there be more stages in a product lifecycle but they need to be redefined. The redefined product lifecycle theory is similar to the understanding of the product lifecycle we know and follow today. Jones structured them as:

The 5 Stages of Product Lifecycle:

- Introduction

- Growth

- Maturity

- Saturation

- Decline

Looking at the face of these theories, they seem different in many ways and they are. This can be just simply down to them being invented through different perspectives. Nevertheless, these theories highlight similar key elements. During the growth stage, profits were high but declined during the maturity stage. Which for many reasons were caused by competition.

The Common Conclusion

Until the mid-1980s, the ‘rules’ of product pricing based on lifecycle theory were followed the same. All manufacturers set prices high as possible. Because on the way to the end of product life; every price was dictated by the market and not the manufacturers.

Besides, it was clearly understood that no product remains constant in a stage forever. They all have a limited life. Some perhaps are longer than others but they will all go through the product life cycle. Following this, the terminology of product lifecycle was altered once more and remains as what we understand today.

The 4 Stages of Product Lifecycle

In the present era, Raymond Vernon’s version is commonly known and vastly accepted terminology for product lifecycle in all industries and academic teachings, which is:

- Introduction

- Growth

- Maturity

- Decline

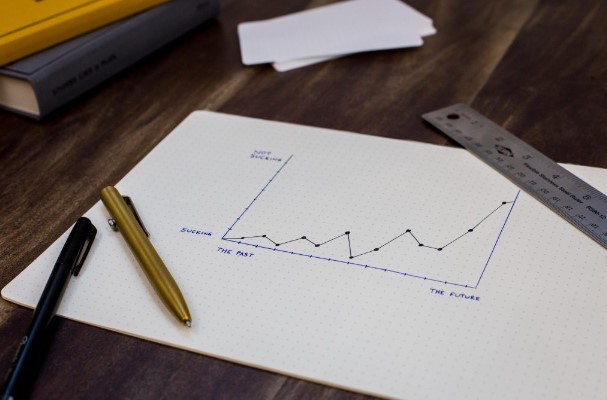

Initially, the product lifecycle was seen as a model for marketers and economists to gain maximum return from a product. The past made it easier for them to analyze and predict the outcomes of a product’s life. This was all great, it allowed corporations to save time and cut some costs but room for improvement was still at large.

The First Leap Into PLM

You can ask anyone in the PLM industry or go on the world wide web, you’ll find the same common answer, that the infamous American Motors Corporation (AMC) first initiated PLM in 1985. They took the first leap when searching for results to enhance the product development process for their Jeep Grand Cherokee.

Consequently, as we all know the results exceeded all expectations. Therefore, we can see the huge success marked in the history books. AMC’s approach was so notable that it sparked an interest that led to Chrysler acquiring American Motors in 1987. Chrysler was then able to maintain manufacturing at the lowest cost for the decade to come.

How and Why PLM?

The first initiative was to increase the productivity of the workers in charge of detailing technical plans and drawings, also known as ‘Draughtsmen’. This proceeded with the use of computer-aided design (CAD) tools.

Instantly increased not only accuracy but consistency collectively in designing. While the efficiency of managing them increased also as a result of being stored in their database.

The next stage was to get as many procedures during the production of a product on a computerized system. This changed the way engineering processes were carried out. Permitting users to quickly access documents in order to change or amend errors. You may think wouldn’t every corporation be taking a computerized transition? In fact, during that time everyone in the industry had the same idea to make all sectors computerized.

How is PLM Different

However, PLM was not only about computerizing but in fact taking another step further. PLM was and still is, an information management system designed to integrate data, processes, business coordination, and individuals in a complete enterprise. It was primarily developed as a manufacturing tool. American Motors utilized it to minimize its production time so would be the one to enter the market first with new products.

In any industry, the fundamentals of a product were the same. During the time from concept to production, the competition was minimal. On the other hand, the highest set of costs relating to any product was the development costs. Therefore, once the growth stage was accomplished, manufacturers only had a short window of opportunity to grasp a large segment of profits. The methods used were correct but they also operated with constant pressure. As one miss calculation of the opportunity would result in substantial setbacks. This was the foundational need for a PLM.

The ideology of developing a PLM is to facilitate progression in corporations. PLM aims to:

- Reduce product development costs

- Reduce overall time from concept to consumer

- Increase production volume

- Increase and manage product quality and costs

Above is a brief list of supports a PLM can provide a corporation. As a result, it also aided in reducing overall manufacturing costs. Consequently, the demand was minimized when the short window of profits came as the manufacturers had already cut down on a substantial amount of costs.

PLM in The Present Era

Over the past 3 decades, PLM has evolved far greater than just being a manufacturing tool. Today there are numerous PLM providers. Supported by the use of modern technology, the benefits have excelled further than initially intended.

The term ‘PLM’ is now commonly used to represent a set of software integrated. It’s the go-to digital solution for corporations. They can now manage the lifecycle of a product, from concept to sales. The ideology remains the same as it did with AMC.

However, in the present era, an efficient and effective PLM system is completely integrated through the same data and information within a corporation. Consequently, ensuring data reliability and decreasing errors.

Do You Need a PLM

As mentioned before, PLM is not just an assisting tool, it exists as its own entity. As a result, according to Business Insider, they estimate the global PLM market size to reach 36.09 billion USD by 2025. In short, PLM is definitely a big deal. It has expanded beyond car manufacturing to multiple industries including:

- Fashion & Brands

- Consumer Goods

- Home Decor & Furniture

- Food & Beverage

The above list is scratching the surface of industries that PLM evolves within. So there is no doubt, for a corporation to survive the fast-paced world we live in today, they certainly need a PLM.

Not Everyone Has a PLM Solution

The sound of having a PLM solution is immense, but yet not every brand or manufacturer has one. This is primarily down to the price tag for having such a facility. Because, the providers sold it as a luxury, not a necessity. Therefore, only large multi-million corporations could afford PLM software solutions.

The reasons for the huge price tags are because, during the past decade. Everyone saw PLM as a business opportunity, rather than providing solutions. Hence, the leaders of PLM systems were individuals who either had capital or software development knowledge. There is nothing wrong with that, the two things are very important in any development of a system not only for PLMs. Nevertheless, most lacked the same experience as people who would be using PLM, resulting in a longer time to develop plus not achieving maximum effectiveness.

The Future of PLM

For many years, PLM solutions/software, or in any form of its nature, has been dominated by large corporations but as we know the present era is on the verge of SME rising. Likewise, the PLM market is going through the same transition.

New PLM software solutions are providing the same or even better solutions at a fraction of the price of leading PLM providers.

a New PLM Solution

Some rising enterprises have taken it further like Bombyx PLM, driven by innovation to offer an efficient and cost-effective software solution. In addition, the Founder, Lucy Blackley designed Bombyx PLM but first worked in the product development industry for over 12 years, therefore truly acknowledging the short backs encountered during processes. Lucy designed Bombyx PLM from an industry worker’s perspective. Along with providing solutions, Bombyx aims to encourage ethical and global sustainability.