People-Centred Product Lifecycle Management and Digital Product Passports

Continuous innovation makes it challenging to find optimal business solutions. The emergence of new technologies during the digital age and the Fourth Industrial Revolution further complicates the matter.

We’ve compiled a list of top technologies that can benefit manufacturing to aid in your decision-making. Prioritizing their implementation and assessing their potential impact on your company can help you make informed decisions.

PLM Tools

Product lifecycle management software manages the entire lifecycle of a product, bringing together people, data, processes, and business systems to improve efficiencies, reduce time to market, and improve product quality.

Furthermore, these systems can help you cope with the increasing complexity and challenges of bringing new products to the fore in a competitive global marketplace.

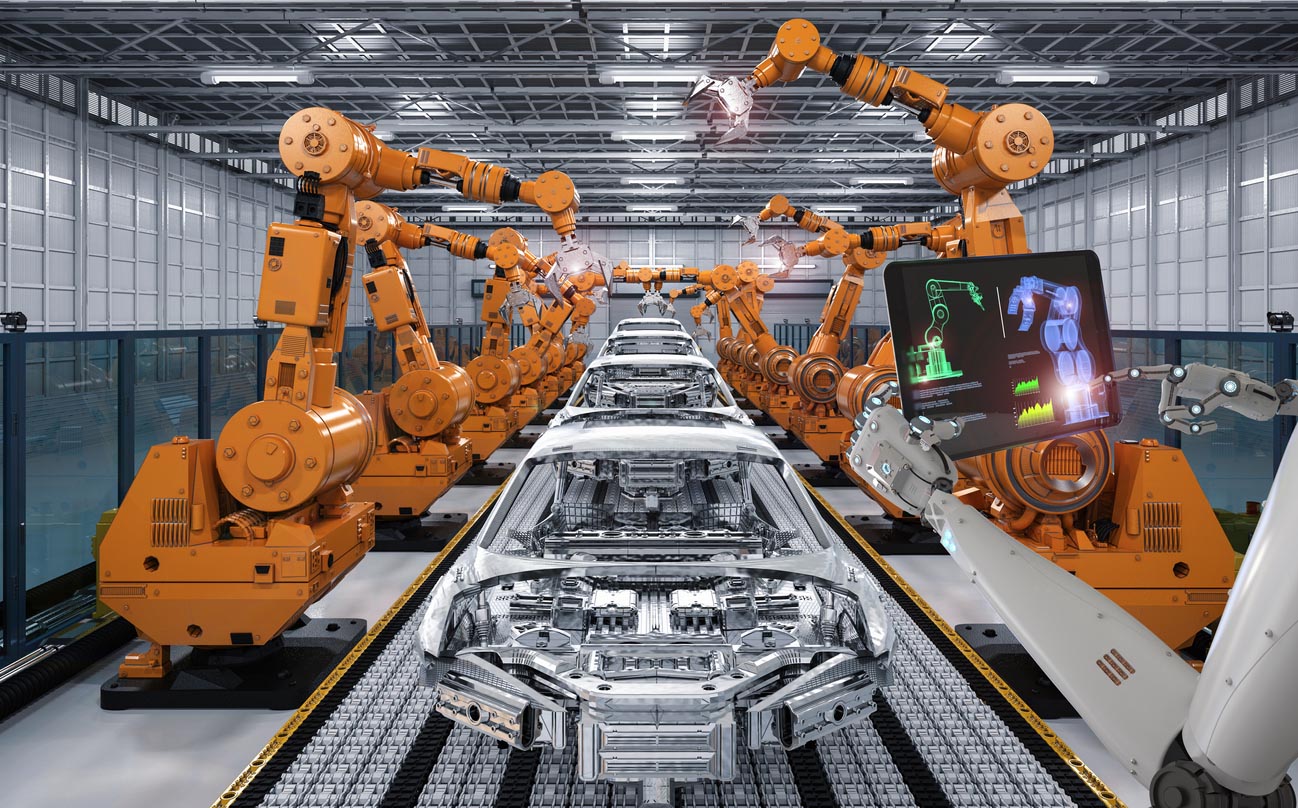

Robotics

While robots are becoming more common in manufacturing, there is no need for concern. By automating repetitive tasks, improving accuracy, and reducing errors, robots allow manufacturers to focus on more productive areas of their business.

Moreover, they offer numerous benefits, including continuous production flow and flexibility. Additionally, software-controlled robots can be reprogrammed without altering the production line infrastructure.

3D Printing

3D printing is a top production technology that reduces design to production times, increases production flexibility, and simplifies the production of prototypes and small runs.

In fact, for faster prototyping, 3D printing is particularly useful. It is inexpensive and produces necessary parts in a matter of hours, allowing for efficient design modifications.

Virtual and Augmented Reality

According to research published by PwC in 2019, virtual and augmented reality technologies have the potential to add $1.5 trillion to the global economy by 2030. Therefore, prioritizing these technologies now could prove fruitful for manufacturing companies.

By adopting this kind of technology, businesses can identify unsafe working conditions, assist in repairing and maintaining machinery, support quality assurance, identify product inefficiencies, and minimize errors and production downtime.

The Internet of Things

Interconnectivity plays a crucial role in today’s world, with the Internet of Things providing physical objects with the ability to exchange data through sensors, software, and processing capabilities with other systems and devices.

By adopting fully connected manufacturing operations, businesses can improve efficiency by supporting automation, increasing accuracy, productivity, and streamlining functions. Digitalization is another essential aspect that reduces manual processes and entries, ultimately lowering the risk of human error.

Cloud Computing

To stay competitive in the global market, meeting demands for faster delivery times and increased production is crucial. Cloud computing is an effective tool to achieve this.

By storing software and information for businesses through Internet connections, it offers advantages such as greater reliability, cost savings, scalability, and centralized management.